The genset of the Middle East oilfield project has successfully passed the Factory Acceptance Test

Dat: 2023-12-05 Clicks:

Recently, clients of the Middle East oilfield project visited the Tide Power China factory and, accompanied by our technical engineer, successfully completed the FAT acceptance of the container generator set for the project.

What’s FAT?

FAT, also known as factory acceptance testing, is a series of testing and confirmation activities conducted by customers at the manufacturer's production base. This includes checking the integrity of equipment, electrical and mechanical installation, and calibrating key instruments, with a focus on ensuring that the equipment meets technical specifications.

The Project Introduction

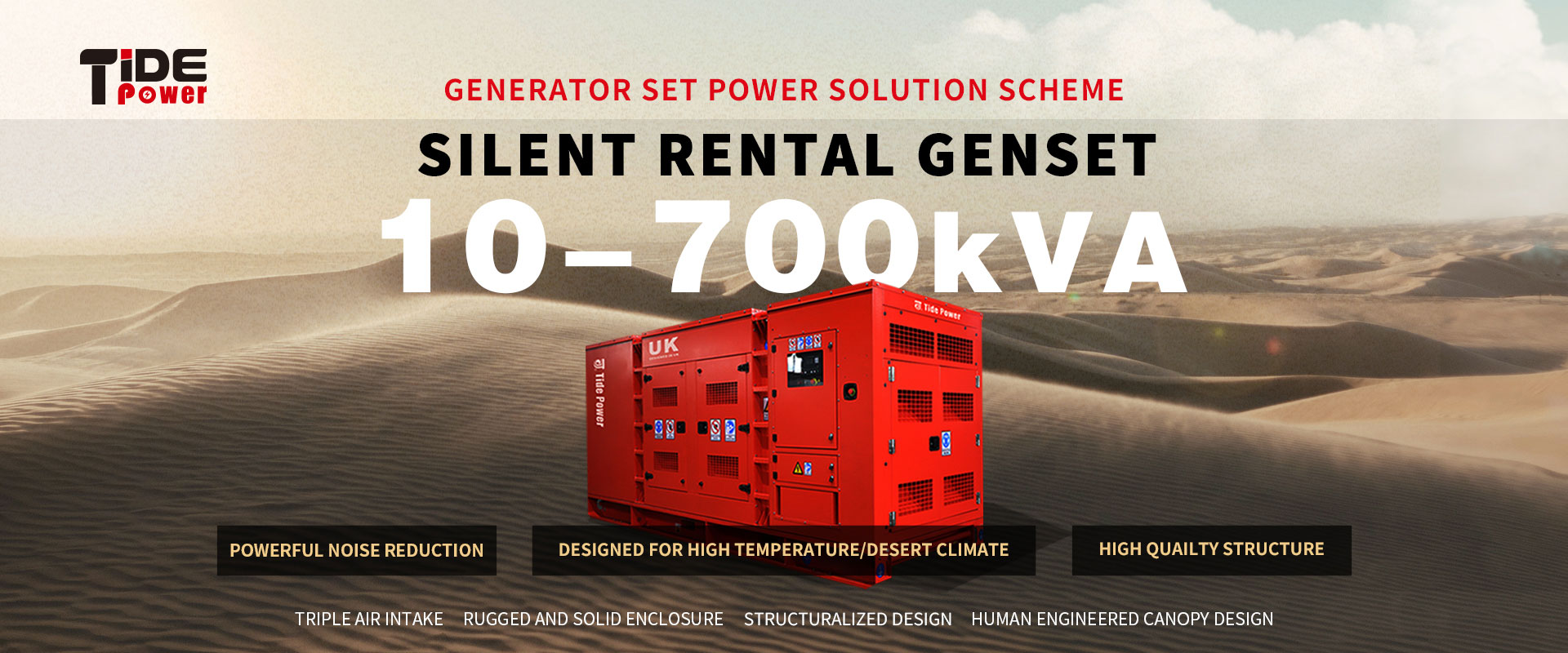

The Middle East oilfield project has a high temperature and drought environment, with a large temperature difference between day and night, which has extremely high requirements for the performance and quality of the generator set. It is necessary to ensure the stability and safety of the equipment during operation.

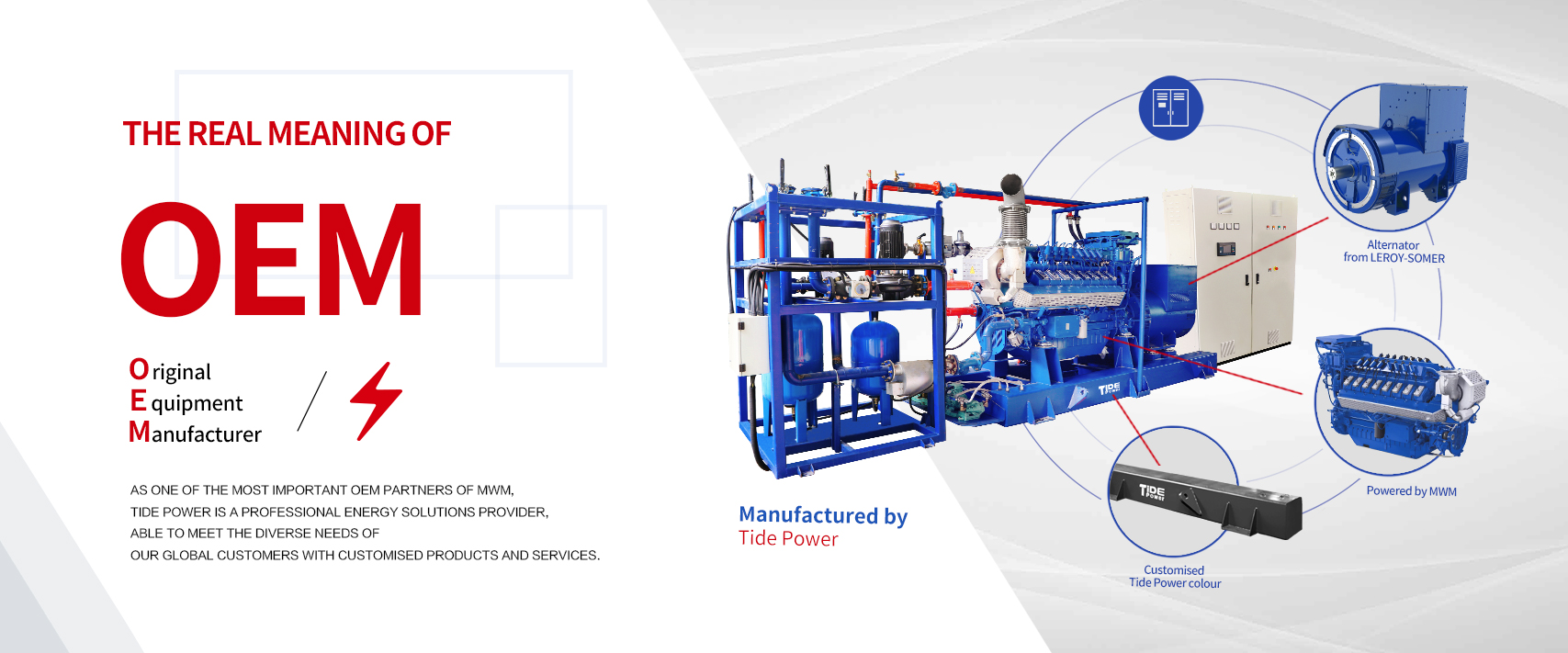

Taking into account the project requirements, the Tide Power technical team has designed a containerized generator set with good heat dissipation, high temperature resistance, and wind and sand resistance to adapt to the desert oilfield environment. It is equipped with a Cummins engine with a main power of 1000kW and a Leroy-Somer LSA alternator to meet performance requirements. Optional components such as space heaters, automatic fire extinguishing devices, automatic refueling systems, and water jacket heaters are also available to meet the personalized customization of the project.

The Factory Acceptance Test

During the FAT process, the customer conducted a detailed inspection of the appearance, electrical wiring, and internal structure of the unit to ensure the integrity of the equipment. According to technical specifications, various performance tests were conducted to verify the performance of the unit under normal working conditions.

After passing the performance test, the engineer conducted a long-term continuous operation test on the unit to check its operational stability and heat management. Strict safety tests, including emergency stop button, overload protection, short circuit protection, etc., have verified the safety of the unit in abnormal situations. In addition, the engineers calibrated all instruments and controllers of the unit to ensure their accuracy and reliability.

After a strict FAT process, the containerized generator set designed by Tide Power for the oilfield project fully meets the technical specifications and customer requirements. This FAT is a complete success, and we look forward to this product playing an important role in the oilfield project in the future. Through the FAT of this project, we have gained richer technical experience in oilfield projects, and will enter a new stage in project management and product quality management.

#Tide Power , #FAT, #oilfield, #generator, #engine

English

English

Home

Home Phone

Phone Message

Message