Diesel generator set noise categories and noise reduction measures

Dat: 2023-03-31 Clicks:

Diesel generator set noise categories and noise reduction measures

Diesel generator sets are widely used in enterprises and institutions as well as construction sites, the noise during operation is up to 100dB or more, with low frequency characteristics, seriously polluting the surrounding environment. In addition, the staff in the engine room will easily feel dizzy and short of breath in this deafening environment for a long time, which will reduce the work efficiency and endanger their physical and mental health.

The noise of the genset is mainly composed of exhaust noise, mechanical noise, combustion noise, cooling fan and exhaust noise, incoming air noise, generator noise six types of noise sources gathered into a comprehensive sound source.

Generator noise: generator noise includes the electromagnetic noise caused by the pulsation of the magnetic field between the stator and rotor, as well as the mechanical noise generated by the rotation of the rolling bearings.

Exhaust noise: exhaust noise is a high-temperature, high-speed pulsating airflow noise, is the largest energy in the engine noise, the noise can be more than 100dB, is the most important component of the total engine noise.

Mechanical noise and combustion noise: mechanical noise is mainly generated by the vibration or mutual impact caused by the cyclic changes in gas pressure and motion inertia force during the operation of the moving parts of the engine.

Cooling fan and exhaust noise: unit fan noise is composed of eddy current noise, rotating noise and mechanical noise. Exhaust noise, airflow noise, fan noise and mechanical noise will spread out through the channels of exhaust air, thus causing noise pollution to the environment.

Air inlet noise: The air inlet channel of the unit must enable the inlet air to enter the machine room smoothly, but at the same time, the mechanical noise and airflow noise of the unit will also be radiated to the outside of the machine room through this air inlet channel.

Noise reduction programmes for generator rooms.

1、Reducing exhaust noise. Exhaust noise is the main noise source of the unit, which is characterized by high noise level, fast exhaust speed and great difficulty in treatment. Special impedance type composite muffler can be used to reduce the exhaust noise by about 30dB (A).

2、Reduce axial fan noise. When reducing the noise of cooling fan of generator set, it is necessary to consider two issues, one is the pressure loss allowed by the exhaust channel. The second is the amount of sound dissipation required.

3, engine room sound insulation. Diesel engine mechanical noise and combustion noise selected approach is in addition to the necessary and observation room connected to the inner wall observation window, the rest of the windows are removed, all holes, holes to be sealed tightly, the wall sound insulation requirements to 40dB ( A ) above. The doors and windows of the machine room should be fireproof and soundproof.

4, air intake and exhaust. The air inlet should be set in the same straight line with the generator set and the exhaust air outlet. The air inlet should be equipped with a resistive piece muffler, as the pressure loss at the air inlet is also within the permissible range, which can make the inlet and outlet air volume in the machine room naturally reach a balance, and the effect of ventilation and heat dissipation is obvious.

5. Sound absorption treatment. The five walls of the engine room, except for the ground, can be used for acoustic treatment, and the perforated plate resonance acoustic structure or superstructure acoustic material can be used according to the spectral characteristics of the generator set.

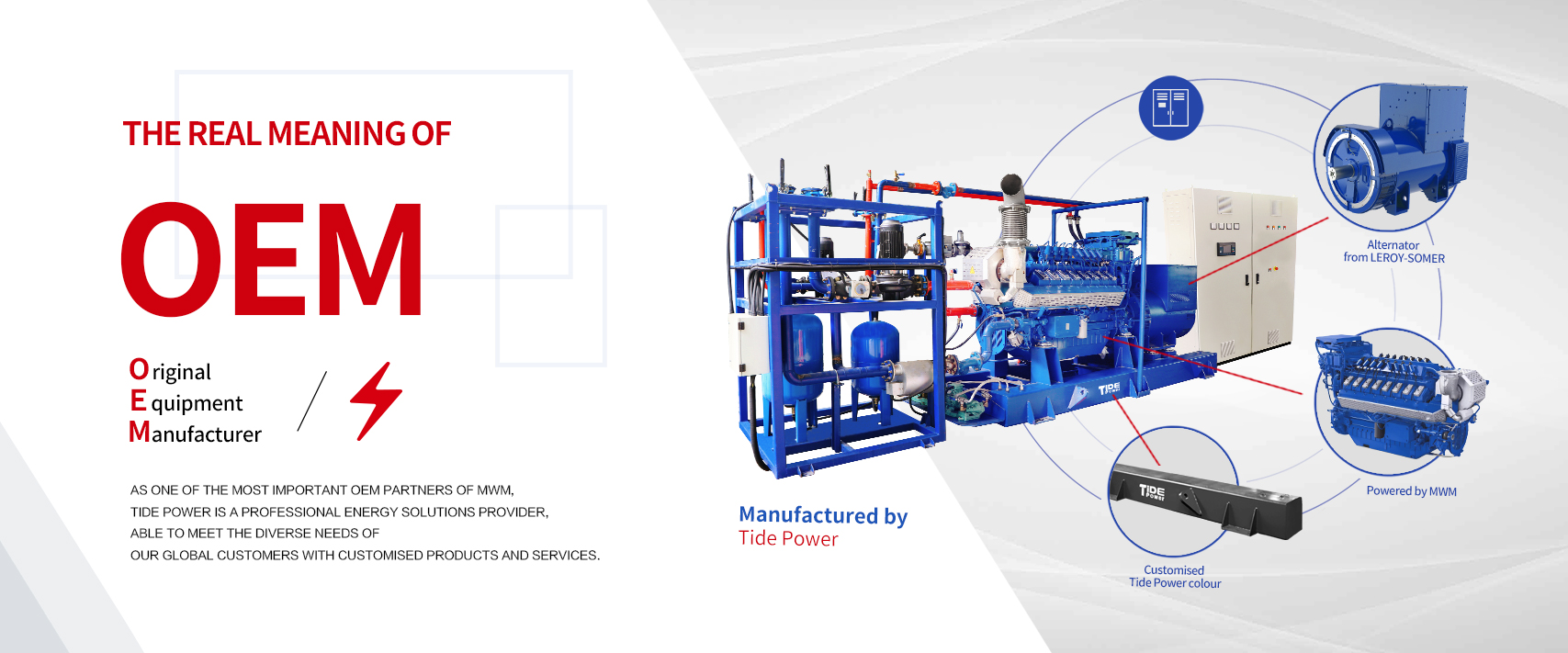

Tide Power is a professional energy solutions provider with products and services covering more than 80 countries and regions around the world. With a professional technical team and efficient service response mechanism, we can deal with customers' needs in a timely and effective manner and meet their customised requirements.

English

English

Home

Home Phone

Phone Message

Message