Maintenance of Diesel Generator Sets

Dat: 2023-09-04 Clicks:

About the maintenance of diesel generator set is an important part of the use of the genset, whether the maintenance of the unit can directly affect the service life of the unit, we have mentioned more or less about the maintenance of diesel generator sets in the introduction of other articles, especially the maintenance of the three filters of air filters, lubricating oil filters and fuel filters, today I will introduce in detail the maintenance methods of these three filters.

The air filter shall not be missed, reversed or misinstalled during installation, and ensure the tightness of each pressing insert. The paper dust cup air filter used, every 50-100 hours of work, to remove the dust 1 time, you can use a soft brush to brush off the surface dust, if the working time exceeds 500 hours or has been damaged, it should be replaced in time. Use oil bath air filter, every 100-200 hours of work, clean diesel fuel should be used to clean the filter element, and replace the lubricating oil in it, if the filter element has been broken, it needs to be replaced immediately, and pay attention to the use of lubricating oil according to the regulations.

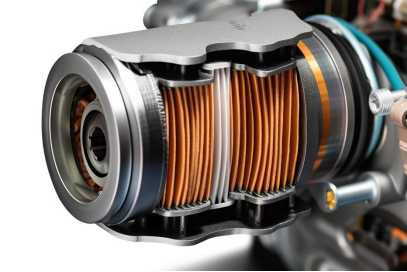

If the lubricating oil filter is not maintained in time during the use of the diesel engine, the filter element is blocked, the lubricating oil pressure increases, the safety valve is opened, and the lubricating oil flows directly into the main oil passage, which will aggravate the wear of the lubrication surface and affect the service life of the diesel engine. Therefore, every 180-200 hours of work of the lubricating oil filter, it should be cleaned 1 time, and if it is found to be damaged, it should be replaced immediately to prevent impurities from entering the lubricated surface. Diesel engine seasonal use, should also clean the crankcase and each lubrication surface, the method is to use lubricating oil, kerosene and diesel fuel mixed as washing oil, can be added after the lubricating oil is released to clean, and then, the diesel engine runs at low speed for 3-5 minutes, and then drain the washing oil and add new lubricating oil.

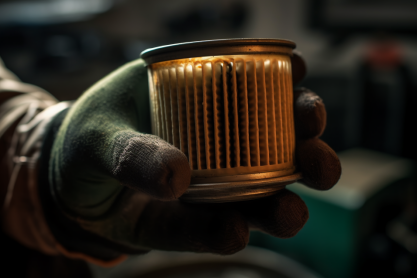

All kinds of fuel filters in the fuel supply system, every 100-200 hours of work, should be removed once or replaced once, and the fuel tank and each oil pipeline should be fully cleaned. Especially for the electronically controlled common rail system, due to the high pressure precision injection, the coupling accuracy of the fuel system is high, and the matching gap is small, which puts forward higher requirements for the filtration efficiency and water separation efficiency of the fuel filter. At present, two-stage filtration systems, first-stage oil-water separators, first-stage diesel fine filters, water separation efficiency requirements greater than 95%, particle filtration efficiency 3-5 micron filtration efficiency greater than 98.6%. During daily maintenance, special care should be taken to find abnormalities, or the mileage and time reach the engine regulations, and need to be replaced in time. During seasonal oil changes, the components of the entire fuel supply system should be cleaned. The diesel used should meet the seasonal requirements and be treated by 48 hours of precipitation purification.

As a professional power solution provider, Tide Power has a comprehensive global supply chain system and service network, with a professional talent team from various international offices in China, Southeast Asia, Russia, Australia, and more, serving more than 80 countries and regions worldwide. We adhere to the corporate philosophy of contributing to the global power industry, with the development goal of green and low-carbon, and promote the transformation and upgrading of the industry for green development.

English

English

Home

Home Phone

Phone Message

Message