What are the reasons for the decrease in power of diesel generator sets?

Dat: 2023-09-19 Clicks:

Incorrect use resulting in power reduction

1. Failure to perform the required running-in test run. After a new car or major repair, it should be run in according to regulations before being put into operation.

2. Long term parking without turning off the engine. Long term parking without stalling, using a small throttle idle, the idle time is prolonged, and the water temperature drops below 75 degrees Celsius, exacerbating the erosion of the cylinder wall, reducing the oil pressure, deteriorating the lubrication condition, exacerbating the wear and tear of various moving parts, leading to a decrease in power. Therefore, it is generally recommended to turn off the engine if the use is suspended for more than 15 minutes.

3. Long term overload work. Long term overload work should be avoided.

Improper maintenance and upkeep

1. Delayed adjustment of gas distribution phase. Adjust the valve timing and repair or replace worn parts such as timing gears, cams, follower columns, tappets, etc.

2. Broken or ineffective valve spring. The valve clearance is too large or too small. Replace the valve spring and adjust the valve clearance to the specified value.

3. Incorrect injection advance angle. Correct the fuel injection advance angle.

4. Insufficient or ineffective spring force adjustment. Causing excessive free shaking. Check the speed control system, replace the damaged speed control spring, and adjust the fit gap between the flying hammer and the pin.

5. Fuel injection pump malfunction. Check the fuel injection pump and replace the parts.

6. Fuel injector malfunction. Repair the fuel injector and replace parts if necessary.

7. Excessive carbon buildup inside the diesel engine or blocked exhaust pipes. Remove the cylinder head, remove the internal carbon deposits, and identify the cause of the carbon deposits. Remove the exhaust pipe and muffler, and thoroughly remove any blockages.

8. The piston ring is stuck. The valve stem is not flexible enough to bite, resulting in insufficient compression pressure in the cylinder. Clean and repair, or replace with new parts.

9. Air filter blockage. Clean the air filter and replace the paper filter element.

10. Diesel engine overheating.

11. Moisture or air in the fuel supply system. Remove water and air from the fuel supply system.

12. Fuel filter blockage. Clean the fuel filter or replace the filter element.

13. Air leakage due to wear or burning of intake and exhaust valves and seats. Grinding repair or replacement.

14. Air leakage at the joint between the cylinder head and the engine body. If the cylinder head nut (bolt) is loose, the cylinder gasket is damaged, etc. Tighten according to the specified torque, check the connection between the cylinder head and the body, and replace the gasket in a timely manner (do not reluctantly repair the old gasket). If necessary, scrape the connection surface between the cylinder head and the body.

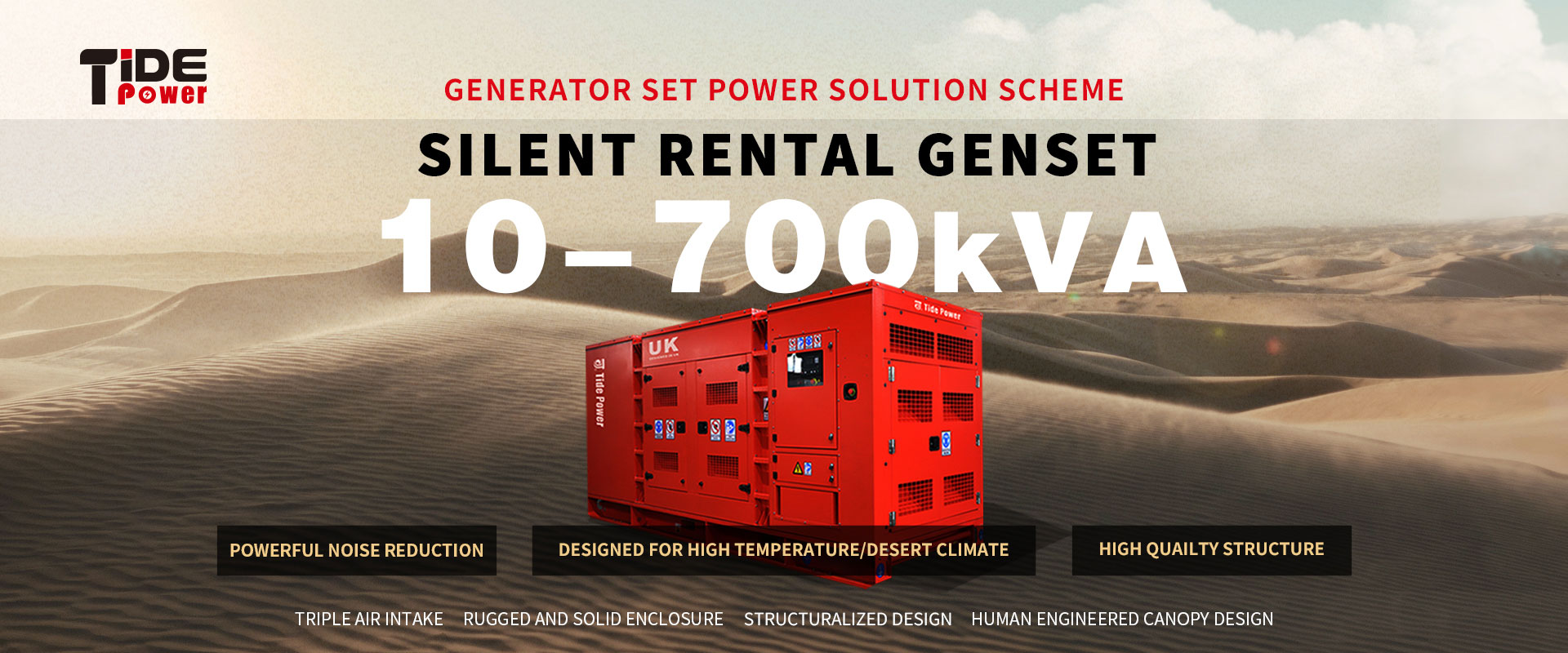

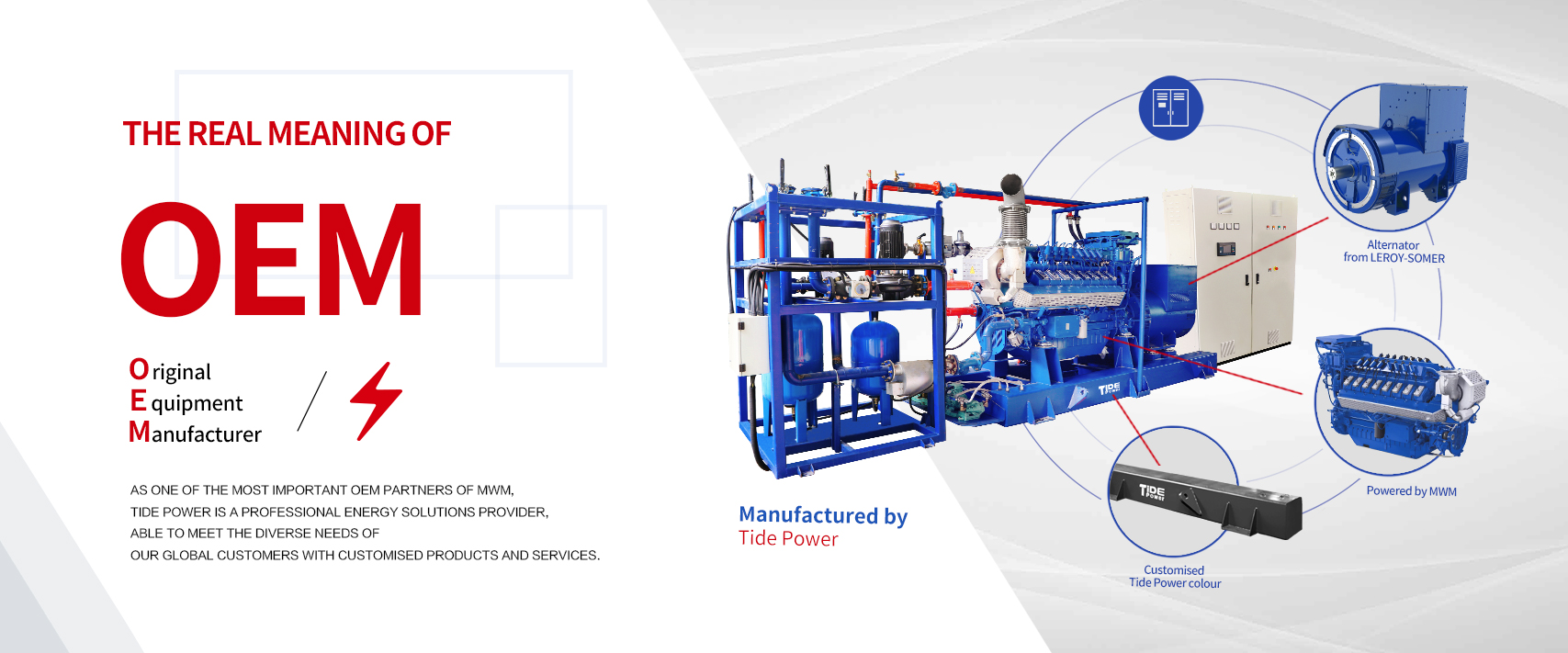

As a professional power solution provider, Tide power has a comprehensive global supply chain system and service network, with a professional talent team from various international offices in China, Southeast Asia, Russia, Australia, and more, serving more than 80 countries and regions worldwide. We adhere to the corporate philosophy of contributing to the global power industry, with the development goal of green and low-carbon, and promote the transformation and upgrading of the industry for green development.

#Tide Power, #diesel, #generator, #power, #engine

English

English

Home

Home Phone

Phone Message

Message