How to protect parts of generator sets from rusting during the rainy season?

Dat: 2023-02-17 Clicks:

The rust prevention of parts of generator sets is related to the service life and stability of the equipment. If the workpiece is rust-proofed well and the product quality is reputable, the business benefits will be high.

Why do workpieces rust?

To solve the problem of rusting of workpieces ,it is first necessary to understand what the root cause of rusting of workpieces is. Workpieces are prone to rusting in various parts of the process, handling, inspection and stock due to moist air and contact with harmful gases in the atmosphere, leading to scrapping or reworking of machined parts and greatly increasing unnecessary production and processing costs.

1、When the acidity of the cutting fluid is too high, the workpiece after chipping and grinding will soon produce floating rust.

2、The products after polishing and grinding are not cleaned and coated with anti-rust oil in time after doing magnetic powder flaw detection, which will produce rust.

3、The workshop hygiene operation is not standardised, resulting in water liquid and acidic cleaning liquid splashing and staining the workpiece, which will then rust.

4、The poor quality of anti-rust oil will cause the workpiece to rust easily and make it difficult to remove rust.

5、Seasonal and environmental factors, especially in summer when the temperature difference is large and the room is humid, the workpiece will absorb moisture and rust quickly.

6、When the workpiece is transported across the industrial plant, because the prevention is not in place, when the rain and snow weather corrosion, cleaning and not timely, not thorough, will lead to serious rusting.

7、The use of acidic cleaning solvents for cleaning before packing will lead to rusting.

8、The workpiece will rust if it is stored for too long before packing and the anti-rust measures are not in place.

9、Shipment and pick-up after packing is not timely and long-term storage will lead to rusting of the workpiece.

Anti-rust treatment of workpieces

Rust prevention measures for workpieces include coating, surface treatment, electroplating, chemicals, cathodic antirust treatment, etc. In the packaging storage and transportation link, the method of applying rust prevention oil is mostly used, and the conventional steps include workpiece pre-treatment and the process of applying rust prevention oil.

1. Workpiece pre-treatment

Surface cleaning: Cleaning must be based on the nature of the surface of the rust prevention material and the environmental conditions at the time, to select the appropriate method. Solvent cleaning method, chemical treatment cleaning method and mechanical cleaning method are generally used.

Surface drying: After cleaning, the surface can be dried with filtered dry compressed air, or with a drier at 120~170 ℃, or with a clean gauze.

2、Coating anti-rust oil

Immersion method: Some small items are immersed in anti-rust grease to allow a layer of anti-rust grease to adhere to their surface. The thickness of the oil film can be achieved by controlling the temperature or viscosity of the anti-rust grease.

Brushing method: Used for outdoor construction equipment or specially shaped products where immersion or spraying is not applicable. When brushing, care should be taken not to create a build-up but also to prevent leakage.

Spray method: Some large antirust objects cannot be oiled by the immersion method and are generally sprayed with filtered compressed air at approximately 0.7Mpa pressure in a site with clean air. The spray method is suitable for solvent diluted rust preventive oil or thin layer of rust preventive oil, but perfect fire and labour protection measures must be used.

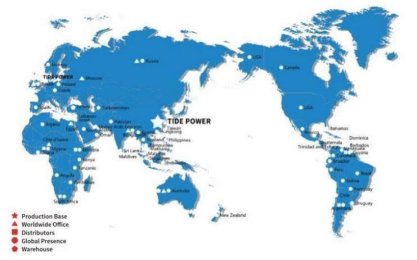

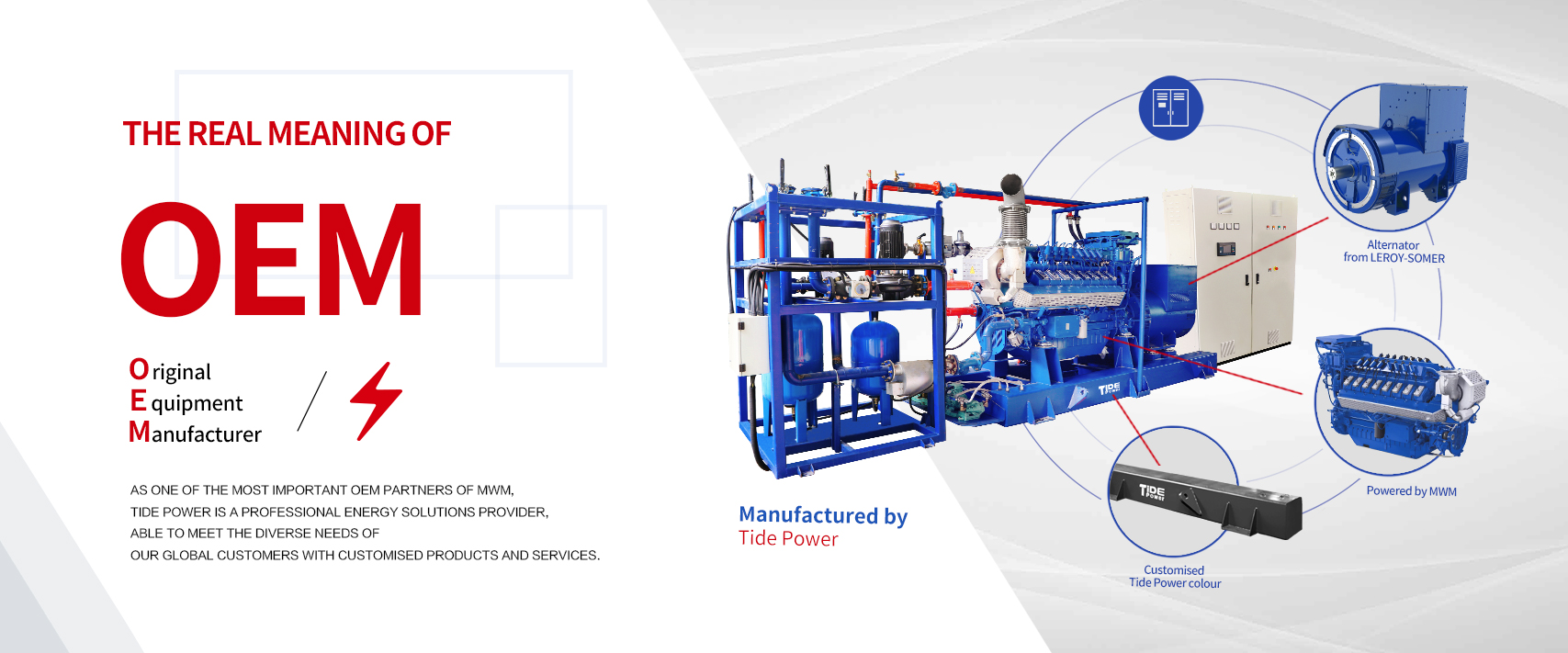

Tide Power is a professional energy solutions provider with products and services covering more than 80 countries and regions around the world. With a professional technical team and efficient service response mechanism, we can deal with customers' needs in a timely and effective manner and meet their customised requirements.

English

English

Home

Home Phone

Phone Message

Message